With the development of society, people`s living standards have improved. Many people no longer consider the price of the car alone when buying a private car, but focus on the appearance of the car. A car with a good-looking design is usually more popular. The purchase price Also higher. However, many people have such a confusion, will a good design increase the design cost? The following is an answer from Shenzhen Industrial Design Company Zunlian.

Let’s take a look at the design process of automobile styling first: market positioning-layout hard point definition-sketches-renderings-CAS surface-sludge model-A surface. The car body we saw was developed by adding engineering structure design to the A side. First of all, the market positioning basically determines the size and style that can be designed. Prior to this, a lot of market research and fashion trend research could not be reflected in simple two sentences. Of course, it also requires capital to do these tasks. It is just a combination of the popular elements on the market, and other cars are to lead the fashion trend. The workload and design cost of this item are very different. The definition of hard point placement means that some modeling constraints will be given based on the manufacturer’s development platform before modeling.

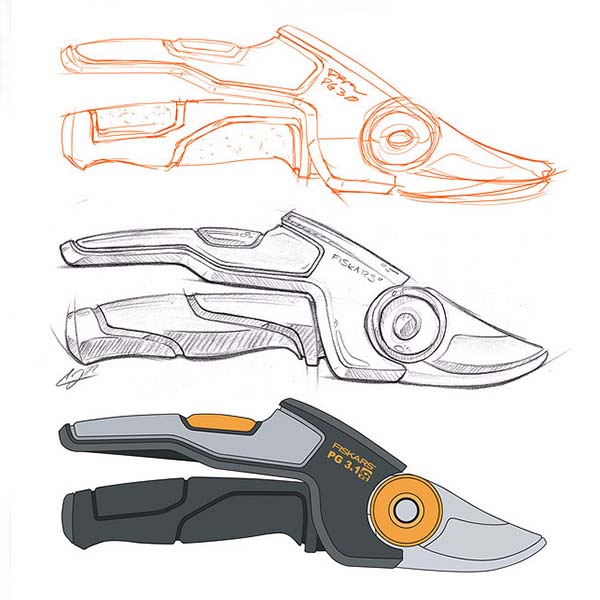

The car is a mass-produced product. If the structure is used, the cost savings are naturally considerable. Therefore, low-end cars for ordinary users usually require more departments to be used and have greater constraints on the shape, so the design is The appearance is often a bit awkward. Sketches-renderings. Needless to say, different design companies have different natural prices. You get what you pay for. Even if it is a single design company, the less money is given to arrange some new people to draw the pictures. The CAS surface is a computer three-dimensional model transformed according to the renderings, and the sludge model is a CNC milling model based on the CAS surface, and then the modeler will make some detailed adjustments on this basis. At this stage, engineering staff will be heavily involved to provide feasibility analysis, so the effect of the clay model will be somewhat different from the initial shape, and the designer and engineer need to compromise with each other. Finally, use the scanner to scan the sludge model into the computer and draw the A side. The above steps require experienced staff, otherwise the renderings and the A side will not be the same car at all.

It can be seen that the more you want to reproduce the awesome styles designed by designers on real car products, the more you have to invest in hiring awesome engineers and purchasing awesome equipment. In addition, the differences in materials, coatings, parts precision and assembly precision are all made up of money, and they are also the result of long-term accumulation of technology. Even if independent brand car companies have money, it is impossible to upgrade their process capabilities overnight. This is why some cars look good at a distance and look at junk up close.

From the above, I believe everyone has a certain understanding of the appearance of the car. A good appearance design must be related to the production cost. Increasing the cost is an inevitable thing. So in the process of buying a car, we see some unique shapes. Cars must not be cheap depending on the price.